Ten 15 MS level scholarships (uptoRs 20,000 per month) for full-time students are available to work on the development of MEMS Gyroscope and accelerometer for Satellite, Mineral Exploration, and Automobile applications

We are a group of Nerds who are doing research for fun to develop something useful to bring comfort in our lives by developing MEMS-based sensors and solutions of the size of the diameter hair. MEMS are very small-scale devices that are of the size of a micrometer (1 million times smaller than a meter). These magical and nonvisible MEMS devices are everywhere around you from airplane to, car to a mobile phone.

Mission

The lab has developed skilled manpower through scientific research to produce world-class MEMS (Microelectromechanical Systems) and microchip design experts having expertise in design, fabrication, and testing to produce world-class R&D in MEMS/Chip development and initiate commercial activities in this area in Pakistan while supporting the local needs of the academic institutions and strategic organizations.

Lab also aims to develop artificial intelligence-based MEMS Inertial Navigation Systems (gyroscope, accelerometers, magnetometer) for mobile robots and other applications.

Objective

-

Develop MEMS and IC (Integrated Chip) Design, Prototyping, and Testing skills through R&D

-

Design and Fabrication of Microgrippers for Molecule Inspection and cell manipulation, Gyroscope, and accelerometer for inertia applications

-

Design and Fabrication of path planning for autonomous cars using a Gyroscope and accelerometer with Artificial Intelligence and Machine learning capabilities.

-

Produce highly skilled manpower at Undergraduate and graduate levels that can take research and development leading jobs in Pakistan and abroad.

-

Provide MEMS design, prototyping, and testing consulting at national and international levels

National Center of GIS (Geographic 10 Information System)& Space Applications, HEC Funded

National Center of GIS (Geographic 10 Information System)& Space Applications, HEC Funded

Funding Agency: HEC

Scholarships available: 10 MS for Rs 20k and 2 PhduptoRs 45k

Starting Date: February, 2022 for 18 months

Amount: Rs 22 Millions

.

• Development of a high-resolution nano-g MEMS accelerometer in applications of Remote Sensing and GIS e.g., inertial navigation, earthquake detection and observation, seismological studies, seismic surveying, spacecraft guidance, geophysical sensing, etc. The development of the aforementioned accelerometer will result in greater accuracy in the measurement of gravity, resource exploration, and seismic monitoring.

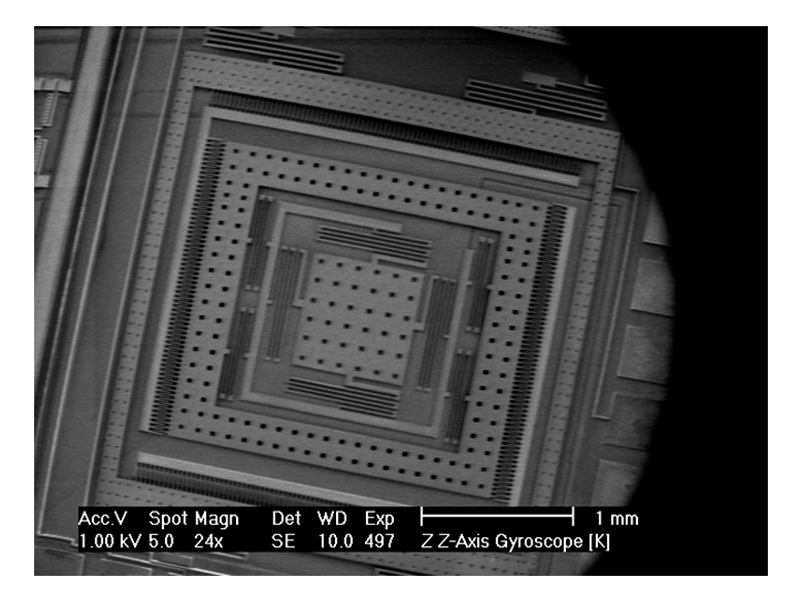

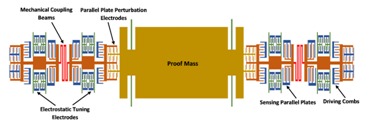

• Development of a dual-mass tuning fork MEMS gyroscope to achieve higher accuracy, higher robustness and insensitivity against external perturbations (vibrations and shock) and better reliability with the space and other defense inertial applications.

MEMS Sensor and chip design and Testing lab under the National Center of Robotics and Automation[Rs 75 Million]

Funding Agency: HEC

Scholarships available: 3 MS for Rs 20k and 1 PhduptoRs 45k

Starting Date: July, 2018

Amount: Rs75 Millions

The lab will develop skilled manpower through scientific research to produce world class MEMS experts having expertise in design and testing to produce world class R&D in MEMS and initiate commercial activities in this area in Pakistan. Moreover, it will support the local needs of the academic institutions, strategic organizations especially the research groups working in the field of robotics and automation. Design, simulation and testing of MEMS based devices including MEMS physical sensors, micro-robotic actuators, RF-MEMS and energy harvesters at the microscale will be carried at the lab.

Development of a MEMS Gravimeter for Mineral Exploration using Measurement of Earth Density Variations, NRPU, HEC Rs 10.8 Millions)

Development of a MEMS Gravimeter for Mineral Exploration using Measurement of Earth Density Variations, NRPU, HEC Rs 10.8 Millions)

Funding Agency: HEC

Scholarships available: 5 MS for Rs 20k and 1PhduptoRs 45k

Starting Date: February, 2022

Amount: Rs 22 Millions

Development of an ultra-low-g highly sensitive gravimeter in the applications of MEMS gravimetry and seismology e.g., mineral exploration, measurement of earth’s density variation, earthquake detection and observation, geophysical sensing, etc. The development of such a gravimeter will result in greater accuracy in the measurement of gravity and mineral exploration. This requires readily available, low cost, highly precise, and low cost inertial sensors. Among these inertial sensors, the advancements in the design and production of low frequency MEMS accelerometers is indispensable for earthquake monitoring and seismic surveying. Geometric Anti-spring (GAS) technology has been used for lowering the spring constants of accelerometers in macro scale for a while now. A similar principle can be used for MEMS gravimeters, for which the GAS typically consists of a set of curved, pre-stressed springs attached to the proof mass. The springs can be compressed or loaded passively with a force due to earth gravity, or actively with a dedicated actuation system. The compression of the springs effectively decreases the resonance frequency along the axis of the sensitivity of the mass-spring system, which significantly increases the sensitivity of the gravimeter. The negative stiffness property of other springs as curved beams has also been utilized in literature for the purpose of lowering the spring constant hand hence reducing the resonant frequency of the device

Our Team

Our Student

Project: MEMS based Inertial Navigation Systems Integration using Artificial Intelligence for Land Vehicle Navigation

Project

MEMS-based Inertial Navigation Systems Integration using Artificial Intelligence for Land Vehicle Navigation

Undergraduate Students

Projects

IMU-based Gesture Controlled Mobile Robot:

We have implemented a system-level application through which the user can give commands to wireless robots using gestures based on motion capture sensors mounted on the human hands and joints. Through this method the user can control or navigate the robot by using the gestures of the hand, thereby interacting with the robotic system. The command signals are tracked using the motion sensors. The gestures provide a rich and intuitive form of interaction for controlling robots. Application areas are Medical Surgery, Surveillance Robots, Motion Capture Tools

Implementation of Inertial navigation system for Autonomous Path Planning of Mobile Robot:

We have implemented a system-level application through which a robot can navigate autonomously from a starting point to an endpoint, the on-board integrated controller creates the necessary trajectories that will drive the robot. The on-board Inertial sensors measure the motion parameters of the robot and the controller estimates the position, velocity, heading, and orientation of the robot. The onboard controller also implements steering correction in case of deviation from its reference heading. Application areas are Autonomous Robots, Autonomous Cars, Surveillance Robots, Guidance Systems, and Navigation Systems.

Fundings (Past)

-

Ignite Technology Fund, 2008, 2012, 2015, Rs 40 Million

-

HEC, 2007, 2008, 5 Million

-

NESCOM, 2012, 0.5 Million

Software Facilities

-

Intelligence

-

MEMSPro

Publications

65 Research Publications in International Journals and Conferences

Collaborations

-

Queen University, Kingston, Canada

-

Air University, Islamabad

-

EME College, Rawalpindi

-

First MEMS Design Startup in Progress

Hardware Facilities

-

Robotics Platforms

-

Microsystem Analyzer Shaker

-

High voltage Amplifiers

-

Probe Station

-

Signal Generators

MEMS Chips Developed

Academics contribute specialist courses in power systems and broad power engineering areas of electrical engineering-based specializations.

Fabrication

We are in the process of establishing a MEMS fabrication facility to offer custom process solutions to meet the requirement of academic researchers and industrial customers. Our facilities include a class 100/1000 clean room environment having the following process capabilities.

Standard capabilities:

Photolithography

- Photolithography of 1µm feature on 6” (150mm) wafers

- Single or double-sided alignment

- Spin & Spray resist coating

Wet Etching

- Anisotropic silicon etching

- Metal etching

- Oxide & Nitride etching

Deposition

- Silicon oxides & nitrides by PECVD

- PVD sputtering of metals, oxides & nitrides

- Oxides or nitrides by reactive sputtering

- LPCVD of SiO2 and Si3N4

- Dry and wet oxidation

- Atmospheric annealing

Reactive Ion Etching

- Deep reactive etching of silicon (DRIE)

- ICP etching of silicon oxide & nitride

Ion Implantation

- Ion implantation of B, P & As @ 200KeV

- Rapid thermal annealing

Metrology and characterization

- Film thickness measurement

- Resistivity four point probe

- Thin film stress measurement

- Ellipsometer

- Optical profiler

- IR microscope

- Optical measuring microscope

- Probe station with parametric analyzer

Dicing & packaging

- Wafer bonder (fusion & anodic)

- Dicing of silicon & glass wafers

- Wire bonder

- Plasma treatment system

![Microgripper to Hold Blood Cells [7] Shaffat A. Bazaz, Fahimullah Khan, Rana Iqtidar Shakoor ”Design, simulation and testing of electrostatic SOI MUMPS based microgripper integrated with contact sensor”, Sensors and Actuators: A. Physical (Elsevier),vol. 167, 2011. [8] Fahimullah Khan , S.A Bazaz, Muhammad Sohail ” Design and implementation of Electrostatic SOI-MUMPs microgripper” Journal of Microsystem Technologies.](https://case.edu.pk/wp-content/uploads/2023/06/pro_1.png)

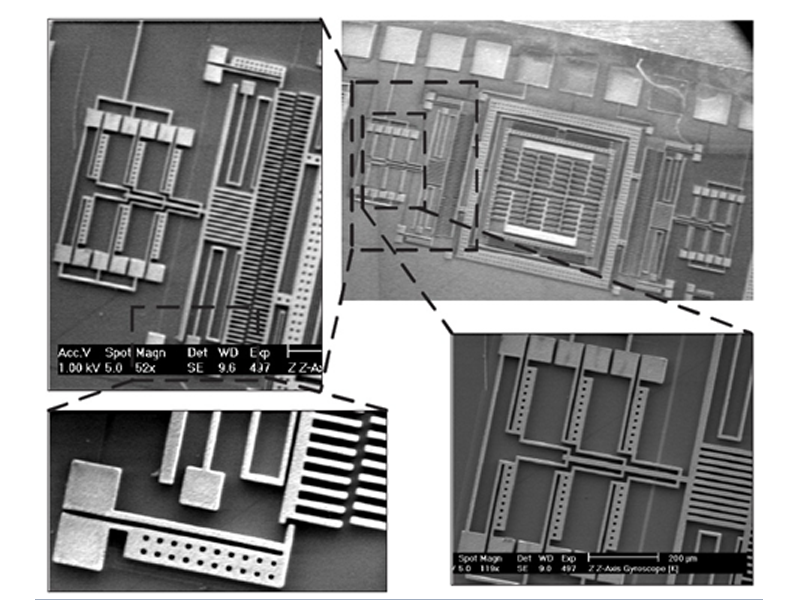

![Thermal MEMS Gyroscope Scanning Electron Microscope pictures of Thermal Micro-Gyroscope developed at CASE [8] Fahimullah Khan , S.A Bazaz, Muhammad Sohail ” Design and implementation of Electrostatic SOI-MUMPs microgripper” Journal of Microsystem Technologies.](https://case.edu.pk/wp-content/uploads/2023/06/pro_2.png)